OUR TECHNOLOGY

CUSTOM SIZING

With a glass processing facility in Singapore, Carlton Glass is able to offer our clients a distinct advantage when it comes to custom options for our glass products.

We are able to work to your exact specifications: producing the size, shape, pattern or design of your glass on very short lead times across the full range of our glass products (including Heat Soak Glass, Tempered Glass, Laminated Glass and Heat Strengthened Glass).

COMPLEMENTARY SERVICES

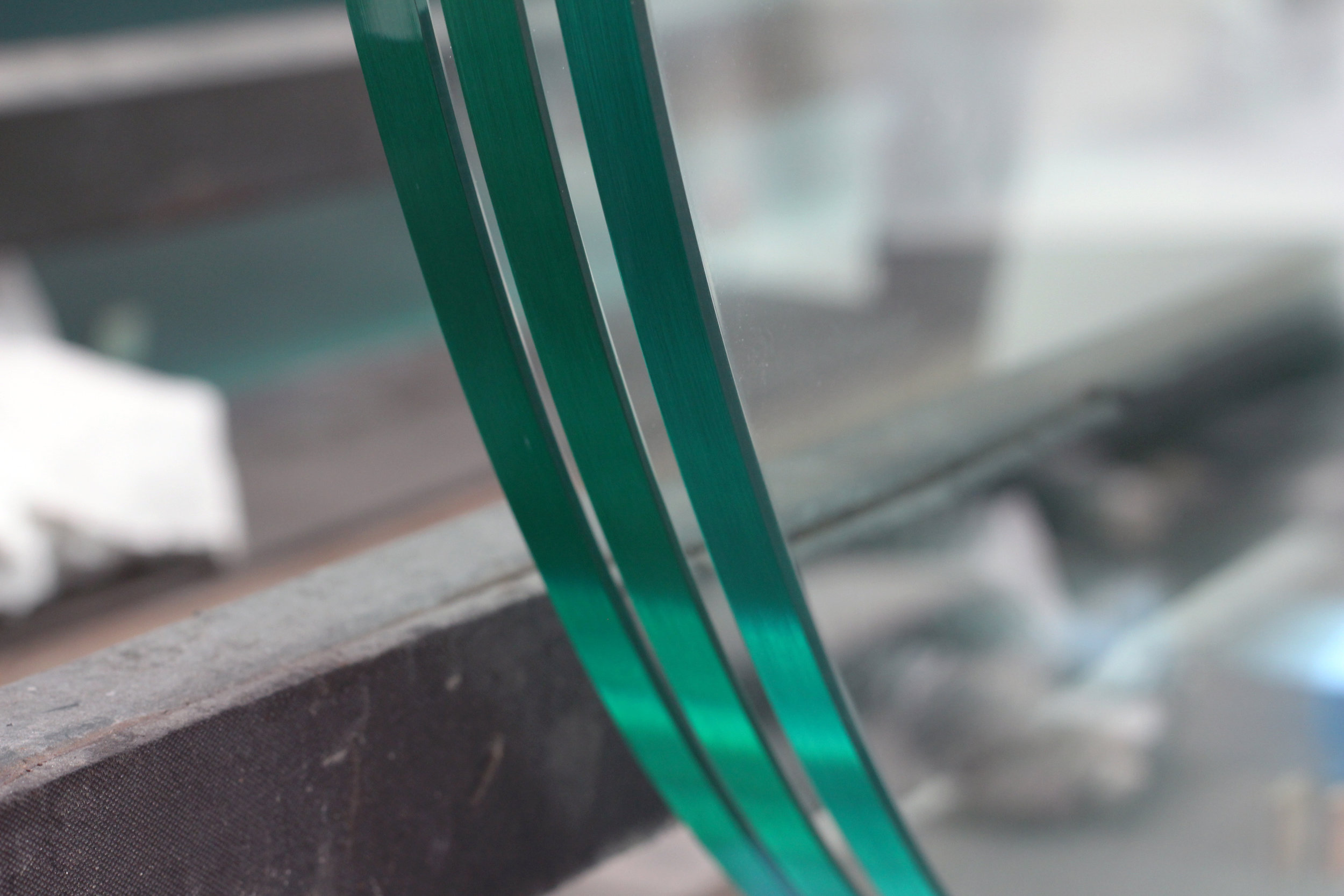

CNC (COMPUTER NUMERICAL CONTROL

Characteristics

• Able to customise to shapes and designs.

• Perfect edge after polishing

• Edge can be exposed with a shining finishing

Disadvantages

• Longer lead time

• Costly

Applications

• Used for meeting room or dining tables, stair railings and counter tops

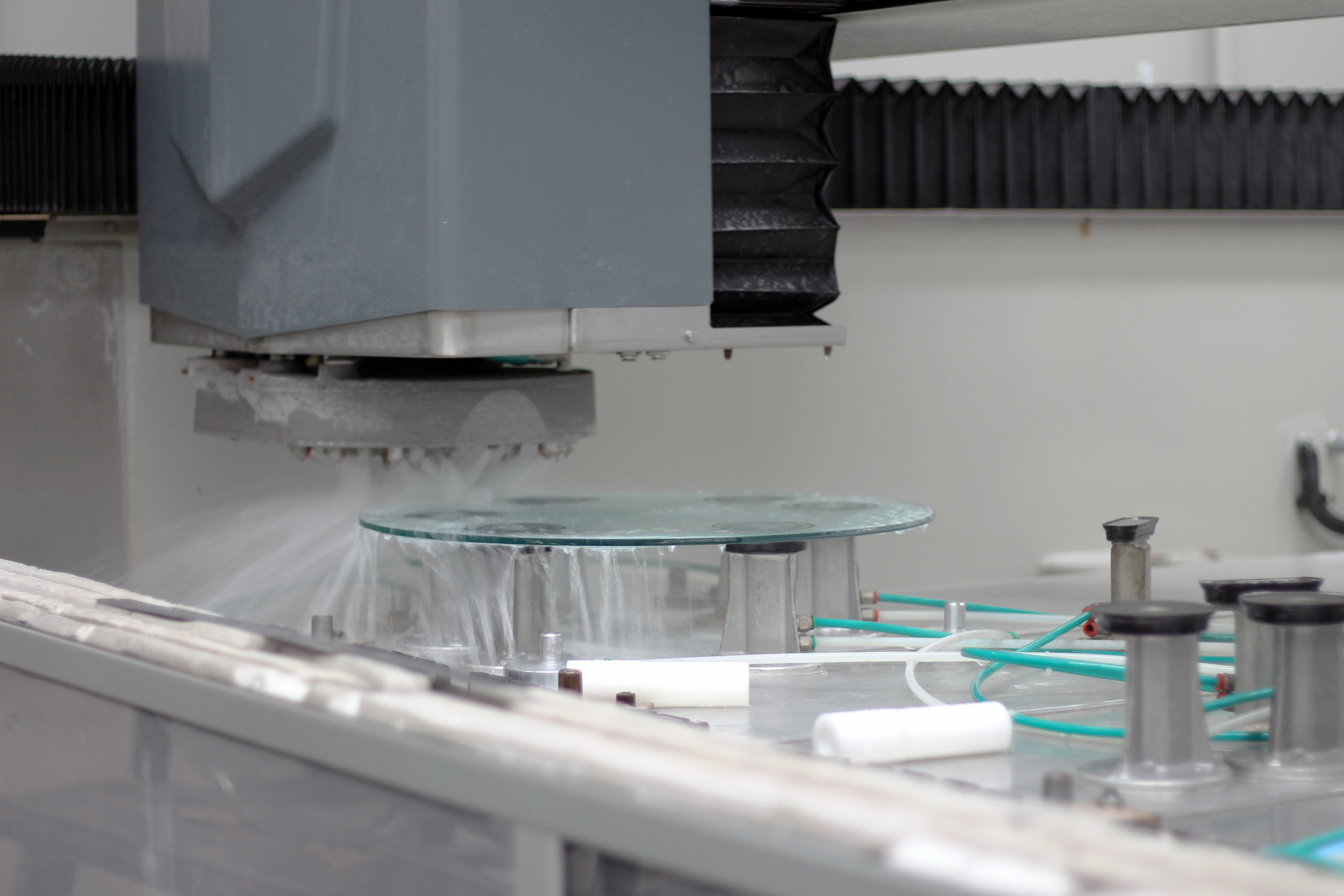

WATER-JET CUTTING

Characteristics

• Able to customise to shapes and designs.

• Close to perfect cutting of gaps

• Less costly compared to CNC

Disadvantages

• Dull finish after polishing

FLAT POLISHING

Characteristics

• Also called straight-line polishing. (90 degree polishing only)

• Shining finishing

• Edge of glass can be exposed.

• Cheapest and easiest way of polishing.

Applications

• Most commonly used.

• Used for doors and shop front panels.